What Affects Fan Performance?

In this article we will take a look at the factors which may effect fan performance. The article will be focusing on fans that are ducted, as this is generally one of the main reasons why your fan performance may be effected.

Factors which can effect the performance of your extraction fan

Adding ducting to a motor will create resistance to airflow. Some motors are much more suitably designed for long duct runs and applications that require a lot of ducting. For more information on motor types view our guide here. Now that we have established this fact we can begin to look at how to minimise this negative effect.

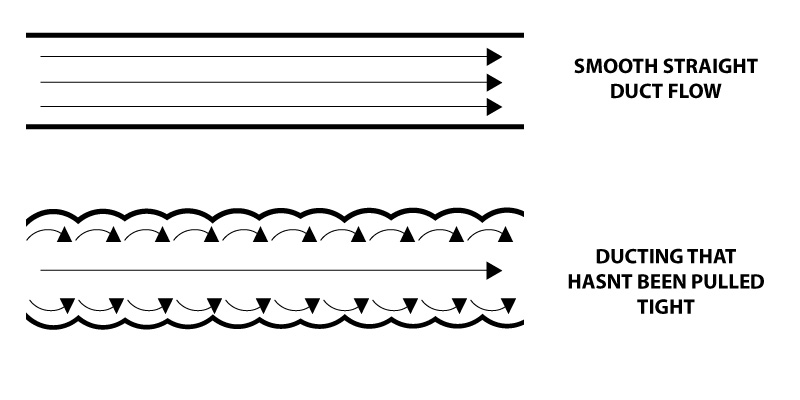

Duct type and how it is installed

Smaller Duct = Increase in airflow resistance

Bends and twists in the ducting = Increase in airflow resistance

Longer duct runs = Increasingly reduced airflow

Try and resist the temptation to use smaller ducting for the fan, if you do need to reduce the diameter of the ducting try to ensure its a small increment. It is a common misconception for people to think that the diameter of the ductwork and piping is not important, or to think that it is suitable to use much smaller duct because of space constraints they may have. By reducing the diameter of the duct you are ‘bottle-necking’ the fan, creating airflow resistance and putting more strain on the motor.

Try to avoid unnecessary bends in the duct work. The advice is always to keep this as straight and direct as possible to increase the efficiency of your fan. If you do need to run the ducting around obstacles try to avoid harsh 90 degree bends, these can create significant restrictions which will lead to reduced airflow.

Performance Issues with an old installation

If you are experiencing airflow issues with an old system, or a system which you have finished installing then there are a few things you can check for. Firstly you should inspect the duct system to ensure there are no holes, leaks. For example sections of duct that should be joined together may have fallen apart. Any gaps will mean air can leak from the system. Carefully check to ensure flexible duct has not been torn or cut by accident during installation.

This article was written on 31st May 2016 by our in house specialist Andy.